Rocketry Work

A showcase of hands-on projects in high-powered rocketry—from custom avionics to propulsion testing. This section reflects practical experience in building, integrating, and testing multiple systems involved in launching solid-fueled rockets.

Avionics & PCB Design

Designed and fabricated custom PCBs for onboard flight computers. Integrated sensors, GPS, barometric altimeters, and communication modules to monitor and record flight data in real time.

Composite Airframe Fabrication

Constructed lightweight yet durable rocket bodies using fiberglass layups. This involved mold-making, layering, curing, and post-processing for aerodynamic optimization.

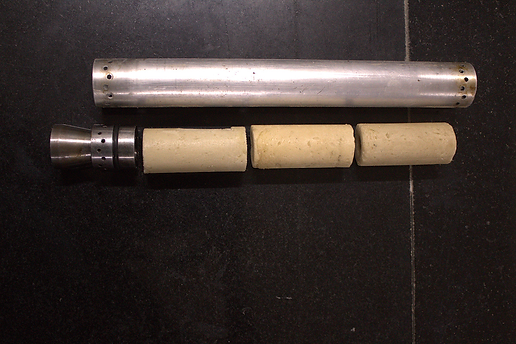

Machined and assembled motor casings from aluminum, ensuring precise tolerances for high-pressure combustion. Included nozzle retention and safe propellant handling features.

Ground Control & Launch Systems

Engineered a modular ground control module for launch operations. Included safety interlocks, wireless arming, and telemetry reception. Ensured reliable control in field conditions.

Static Motor Testing

Built a safe and reliable test stand for static firing of rocket motors. Included thrust measurement and high-speed data logging to analyze motor performance and validate designs.

Solid Propellant Development

Formulated and cast custom solid rocket fuel blends using KNSU and other composite propellants. Focused on consistency, burn rate control, and safe manufacturing protocols.